China Compressors Products Manufacturer

The global compressors market, including China’s segment, is a dynamic and growing industry. The overall global market was valued at approximately $125.75 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 2.8%, reaching around $140.49 billion by 2027. This growth is driven by increased applications of compressors in various sectors, particularly in power industries, fueled by rising global population and power demands.

China’s compressor market is expected to reach $15.7 billion by 2024, growing at a CAGR of 3.5%. This growth is significantly backed by the robust increase in the automotive industry, along with the growing construction sector. Central China, particularly the Hubei province, is expected to be the fastest-growing region within the country, due to its strong industrial base and focus on developing emerging manufacturing industries. The automotive sector is especially significant in this growth, accounting for a substantial share of the compressor market due to the increasing production of motor vehicles and electric vehicles.

A compressor is a mechanical device that increases the pressure of a gas by reducing its volume. Compressors are used in various applications across multiple industries. Here are some common types of compressors and their descriptions:

- Rotary Screw Compressor: This type uses two rotors (helical screws) to compress the gas. It’s commonly used for continuous, high-volume applications such as air conditioning and refrigeration. Rotary screw compressors are known for their reliability and efficiency.

- Centrifugal Compressor: This type uses a rotating disk or impeller to accelerate and then decelerate captured air, which increases its pressure. Centrifugal compressors are often used in large applications like turbine engines in jet aircraft and power generation.

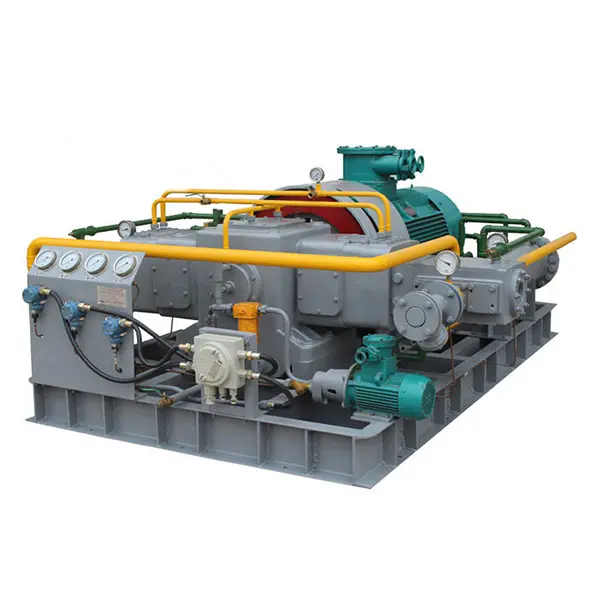

- Reciprocating Compressor: It works similarly to an internal combustion engine. It has a piston that moves within a cylinder to compress the gas. These compressors are typically used for high-pressure applications like gas pipelines and oil refineries.

- Axial Flow Compressor: Used primarily in high-speed engines like jet engines, this compressor consists of a series of fan-like airfoils. It efficiently compresses large volumes of air at high speeds.

- Scroll Compressor: This type involves one stationary and one orbiting scroll to compress gas. Scroll compressors are known for their quiet operation and are used in HVAC systems and refrigeration.

- Diaphragm Compressor: A type of positive displacement compressor, it uses a diaphragm moved by a rod to compress the gas. It’s often used where a high degree of purity is required, as there’s no oil or lubricant in the compression chamber.

- Variable Speed Drive (VSD) Compressor: These are more energy-efficient as they can adjust the motor speed to match the air demand. They are used in applications where the demand for compressed air fluctuates.