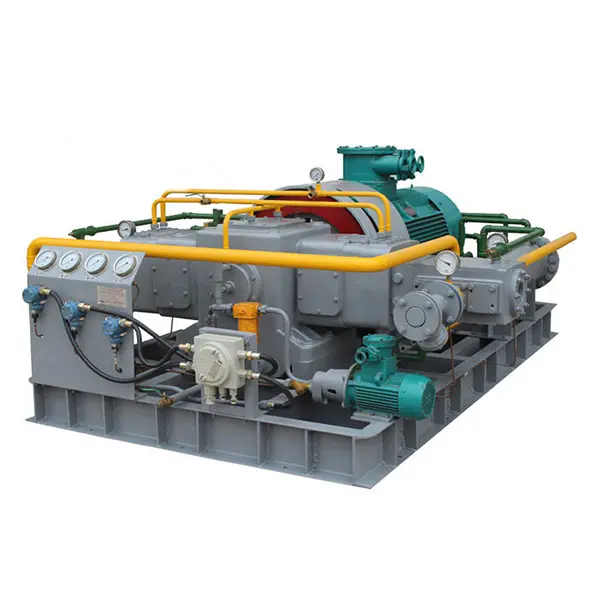

LNG-BOG Compressor

LNG-BOG Compressor

- Brand Huayan Gas

- Place of Origin China·Xuzhou

- Compressor structure: Piston Compressor

- Model: ZW-4/0.5-5 (customized)

- Volume flow: 3NM3/hour~1000NM3/hour (customized)

- Voltage: : 380V/50Hz (customized)

- Maximum outlet pressure: 100MPa (customized)

- Motor power: 2.2KW~30KW (customized)

Description

LNG-BOG Compressor is crucial in the liquefied natural gas industry. To convert it into a liquid state, LNG is natural gas cooled to extremely low temperatures, typically around -162 degrees Celsius (-260 degrees Fahrenheit). During the storage and transportation of LNG, some of the gas naturally evaporates, forming what is known as boil-off gas (BOG).

The flash gas, essentially Boil-Off Gas (BOG), can be efficiently utilized by pressurizing it using a compressor. The pressurized gas can then be directed to the urban pipeline network or transported to a Compressed Natural Gas (CNG) station for various applications.

Compressors designed for BOG recovery are categorized into four primary types based on their normal working flow rates:

- 100Nm³/h (with a range of 50 to 150Nm³/h)

- 300Nm³/h (with a range of 200 to 400Nm³/h)

- 500Nm³/h (with a range of 400 to 700Nm³/h)

- 1000Nm³/h (with a range of 800 to 1500Nm³/h)

These compressors play a key role in efficiently recovering and pressuring BOG, enabling its integration into urban gas pipelines or transport to CNG stations, and effectively utilizing this valuable resource.

Features & Characteristics: LNG-BOG Compressor

- Automation and Control Systems: LNG-BOG compressors often have advanced automation and control systems to optimize performance. These systems can include sensors, feedback loops, and programmable logic controllers (PLCs) to monitor and adjust the compressor’s operation.

- Reliability: Reliability is crucial in LNG operations. These compressors are designed to operate continuously with high reliability, minimizing downtime and ensuring the continuous operation of LNG facilities.

- Integration with LNG Plant: LNG-BOG compressors are integrated into the overall LNG plant or facility. They coordinate with other equipment and systems to maintain LNG production, storage, and transportation efficiency.

- Environmental Considerations: Efforts are made to design LNG-BOG compressors with environmental considerations, minimizing emissions and ensuring compliance with environmental regulations.

- Maintenance Requirements: Regular maintenance is essential for the long-term performance of LNG-BOG compressors. Manufacturers often provide guidelines for maintenance schedules and procedures to ensure optimal operation.

Main structure: LNG-BOG Compressor

- The core component for gas compression

- A power source (electric motor, gas turbine, reciprocating engine) for driving the compressor

- Maintains equipment temperature in the low-temperature LNG environment

- Allows entry of boil-off gas into the compressor

- The area where gas compression occurs, often with multiple stages

- Handles and regulates the flow and temperature of compressed gas

- Provides oil to reduce friction and wear in moving parts

- Monitors and controls parameters for optimal compressor performance

- Includes features like pressure relief valves and emergency shutdown systems

- Supports the compressor and withstands operational loads and vibrations

- Transports gas between different components of the compressor system

Applications: LNG-BOG Compressor

- LNG Storage and Transportation Optimization: By efficiently recovering and pressurizing BOG, the overall efficiency of LNG storage and transportation systems can be enhanced, minimizing gas losses and improving operational sustainability.

- Offshore LNG Production Facilities: BOG recovery and pressurization play a crucial role in offshore LNG production, where efficient gas handling is essential for maintaining operational integrity in challenging offshore environments.

- Emergency Backup Systems: The recovered and pressurized BOG can be a reliable backup source, ensuring a continuous supply of natural gas in emergencies or during unexpected disruptions.

- Environmental Compliance: By preventing the release of BOG into the atmosphere, applying BOG recovery and pressurization supports environmental compliance and reduces greenhouse gas emissions.

| Model | Medium | Flow-rate (Nm3/h) | Intake Pressure (MPa) | Exhaust Pressure

(MPa) |

|

| 1 | ZW-4/0.5-5 | BOG | 300 | 0.05 | 0.5 |

| 2 | ZW-4.0/(1-5)-6 | BOG | 400~1200 | 0.1~0.5 | 0.6 |

| 3 | ZW-0.32/(2-6)-10 | BOG | 50~110 | 0.2~0.6 | 1.0 |

| 4 | ZW-0.32/(3-5)-40 | BOG | 60~100 | 0.3~0.5 | 4.0 |

| 5 | ZW-0.55/6-250 | BOG | 200 | 0.6 | 25.0 |

| 6 | DW-12/2 | BOG | 600 | Normal | 0.2 |

| 7 | ZW-6/(2-6) -7 | BOG | 900~2000 | 0.2~0.6 | 0.7 |

| 8 | VW-14/(1-3)-4 | BOG | 1400~2900 | 0.1~0.3 | 0.4 |

| 9 | ZW-4/(1-6)-7 | BOG | 400~1400 | 0.1~0.6 | 0.7 |

| 10 | ZW-4/(1.5-6)-8 | BOG | 500~1400 | 0.15~0.6 | 0.8 |

| 11 | ZW-2.5/(0.5-4)-(3.5-7) | BOG | 190~640 | 0.05~0.4 | 0.35~0.7 |

| 12 | ZW-0.45/(10-40)-40 | BOG | 250~950 | 1.0~4.0 | 4.0 |

| 13 | ZW-0.4/6-10 | BOG | 140 | 0.6 | 1.0 |