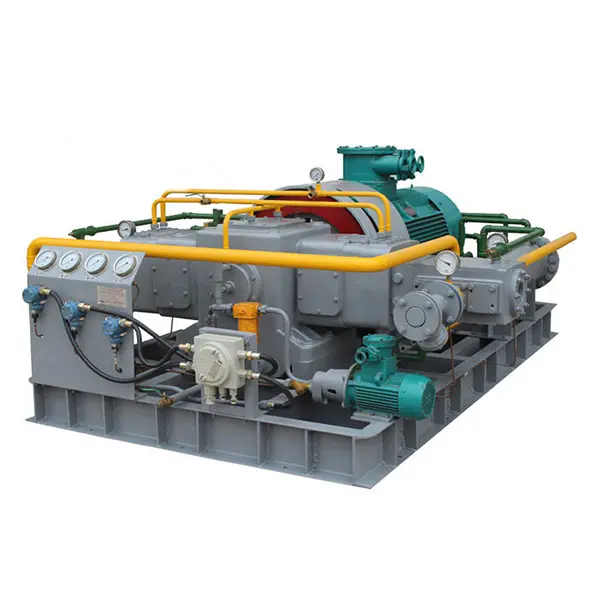

Natural Gas Compressor

Natural Gas Compressor

- Brand: Huayan Gas

- Place of Origin: China·Xuzhou

- Compressor structure: Piston Compressor

- Volume flow: 3NM3/hour~1000NM3/hour (customized)

- Voltage: 380V/50Hz (customized)

- Maximum outlet pressure: 100MPa (customized)

Get Free Quote

Description

Welcome to the world of natural gas compressor—an essential component in the intricate tapestry of the energy sector. With their diverse applications, natural gas compressors contribute significantly to the production, transportation, and utilization of natural gas. From boosting gas pressure in production fields to facilitating its seamless journey through pipelines and supporting emerging sustainable transportation solutions, these compressors are at the forefront of driving efficiency, reliability, and environmental responsibility.

Features & Characteristics:

- Advanced Filtration Systems: Natural gas compressor incorporate sophisticated filtration systems to ensure the removal of impurities and contaminants from the gas stream. This not only protects the compressor internals but also maintains the quality of the compressed gas, meeting industry standards for purity.

- Remote Monitoring and Diagnostics: Leveraging the power of IoT (Internet of Things) technology, natural gas compressors enable remote monitoring and diagnostics. Operators can access real-time data, receive alerts for potential issues, and perform diagnostics from a central control center.

- Energy Recovery Systems: Some compressors integrate energy recovery systems, such as regenerative drives or heat recovery units. These systems capture and repurpose excess heat generated during compression.

- Customization Options: Manufacturers often provide customization options to tailor compressors to specific project requirements. This includes variations in capacity, pressure levels, and integration with other components.

- Comprehensive Documentation and Training: Natural gas compressor have detailed documentation and training resources. This ensures operators are well-versed in the equipment’s functionalities.

Main Structure: Natural gas compressor

- Compression mechanism with one or more stages for efficient pressure increase.

- Cylinder and piston arrangement designed for effective compression.

- Cooling system to manage heat generated during compression, maintaining optimal temperatures.

- Drive system, either electric motor or gas engine, powering the compression mechanism.

- Valve arrangement utilizing inlet and discharge valves for gas flow regulation.

- Control and monitoring systems for real-time oversight and operational adjustments.

- Skid or base frame for stability, easy transportation, and installation.

- Piping and instrumentation network for gas flow control and system connectivity.

- Safety features including pressure relief valves, emergency shutdown systems, and protective mechanisms.

- Materials selection focused on corrosion-resistant components for durability in diverse operating conditions.

Applications: Natural gas compressor

Natural gas compressors find diverse applications across the energy sector, supporting various processes related to natural gas production, transportation, and distribution. Some key applications include:

- Gas Production and Gathering: Compressors play a crucial role in natural gas production fields by boosting the pressure of extracted gas and facilitating its movement through pipelines. In gathering systems, compressors consolidate gas from multiple wells for efficient transportation.

- Storage Facilities: Compressors are employed in underground storage facilities for natural gas. During periods of low demand, excess gas is compressed and stored. When demand increases, the stored gas is depressurized and supplied to meet consumer needs.

- LNG (Liquefied Natural Gas) Production: In the LNG production process, natural gas is compressed to a high pressure before being cooled and liquefied. Compressors play a critical role in preparing the gas for liquefaction.

- Fueling Stations: Compressors are used in natural gas fueling stations for vehicles that run on compressed natural gas (CNG) or liquefied natural gas (LNG). They compress natural gas for vehicle refueling.

- Pneumatic Conveying: Compressed natural gas is used in industries like cement and mining to power pneumatic conveying systems for transporting bulk materials. Compressors provide the necessary pressure to move materials through pipelines.