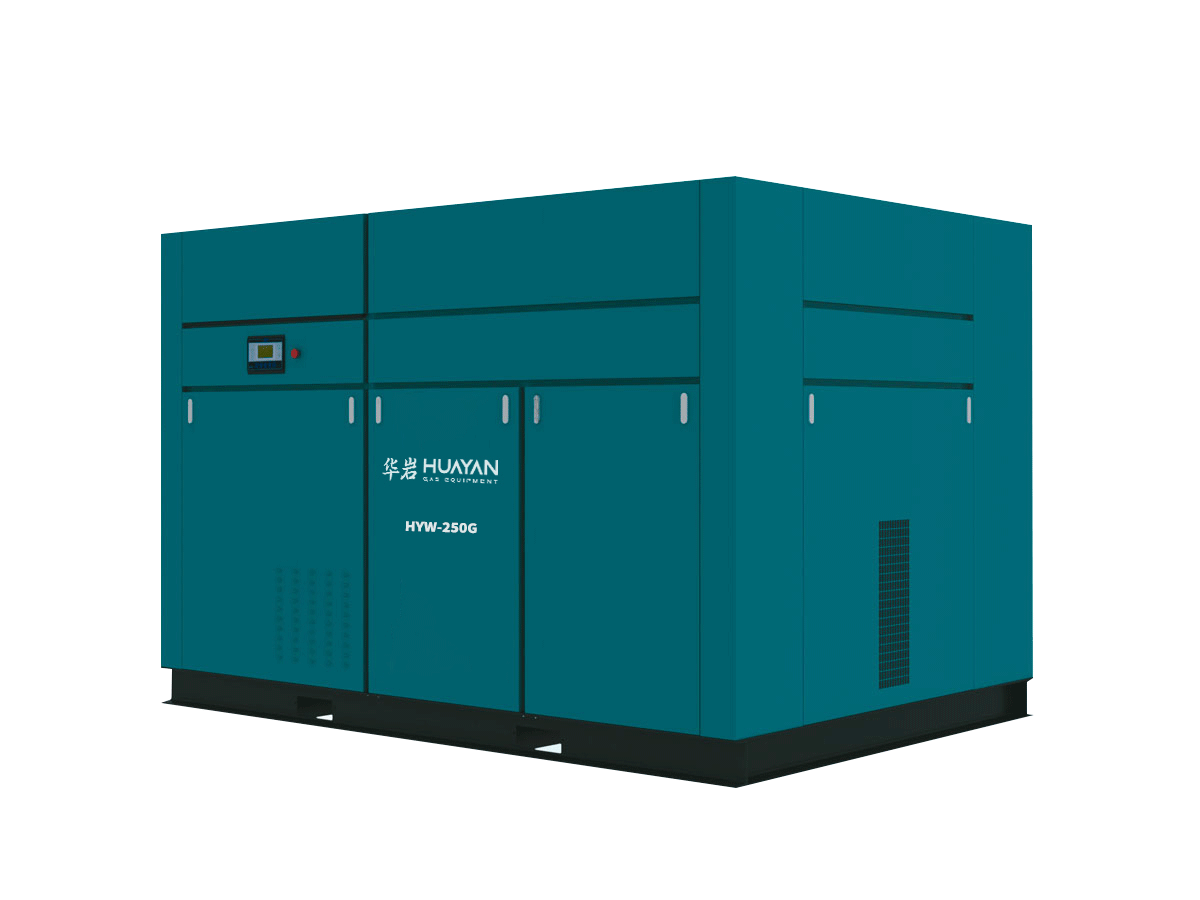

Screw Air Compressor

Meet our Screw Air Compressor – the driving force behind industrial pneumatic excellence. Designed with precision for optimal efficiency, its rotary screw mechanism ensures a consistent flow of compressed air, maintaining seamless productivity. Its space-saving design seamlessly accommodates diverse work environments, meeting the demands of manufacturing, construction, and automotive sectors. The helical rotor construction excels not only in noise reduction but also in providing robust durability for challenging tasks.

Whether you’re in mining, textiles, or food processing, our Screw Air Compressor provides the reliable and clean compressed air you need. Variable speed options enhance energy efficiency, while easy maintenance keeps operations running smoothly.

Features & Characteristics:

Elevate your industrial processes with a compressor that embodies performance, reliability, and adaptability — our Screw Air Compressor is the driving force behind your operational excellence.

- Rotary Screw Mechanism: Screw air compressors utilize a rotary screw mechanism, where two helical rotors mesh together to compress air efficiently.

- Continuous Operation: These compressors provide a constant and uninterrupted supply of compressed air, ensuring a reliable source for various industrial processes.

- High Efficiency: Known for their energy efficiency, screw compressors offer optimal compression ratios, reducing energy consumption and operating costs.

- Low Noise Levels: The helical rotor design contributes to smooth airflow, minimizing vibrations and noise, creating a quieter working environment.

- Durable Construction: Typically constructed with robust materials, screw air compressors are durable and capable of withstanding the demands of heavy-duty industrial applications.

- Oil-Injected and Oil-Free Options: They are available in both oil-injected and oil-free versions, catering to diverse applications and industries with specific air quality requirements.

- Variable Speed Control: Many models feature variable speed drives, allowing users to adjust the compressor’s speed to match the fluctuating demand, optimizing energy efficiency.

- Compact Design: Screw compressors often have a compact footprint, making them suitable for installations with limited space.

- Easy Maintenance: With fewer components and well-engineered designs, screw air compressors generally require minimal maintenance, contributing to cost-effectiveness.

- Pressure Regulation Systems: Equipped with efficient pressure control systems, these compressors allow users to set and maintain desired air pressure levels for different tasks.

Applications

Screw air compressors find widespread applications across various industries due to their efficiency and reliability. Some common applications include:

- Manufacturing: Powering pneumatic tools, such as drills, grinders, and assembly tools, in manufacturing processes.

- Construction: Running air-powered tools at construction sites, such as jackhammers, nail guns, and concrete breakers.

- Automotive Industry: Supplying compressed air for automotive assembly lines and pneumatic tools used in vehicle manufacturing and repair.

- Mining: Providing compressed air for drilling, blasting, and other pneumatic equipment used in mining operations.

- Oil and Gas: Supporting various operations, including well drilling, pipeline maintenance, and offshore platform activities.

- Power Plants: Assisting in various processes, such as controlling valves, cleaning, and providing instrument air in power generation facilities.

These diverse applications showcase the versatility of screw air compressors in meeting the compressed air needs of numerous industries, contributing to the efficiency and productivity of various processes and operations.