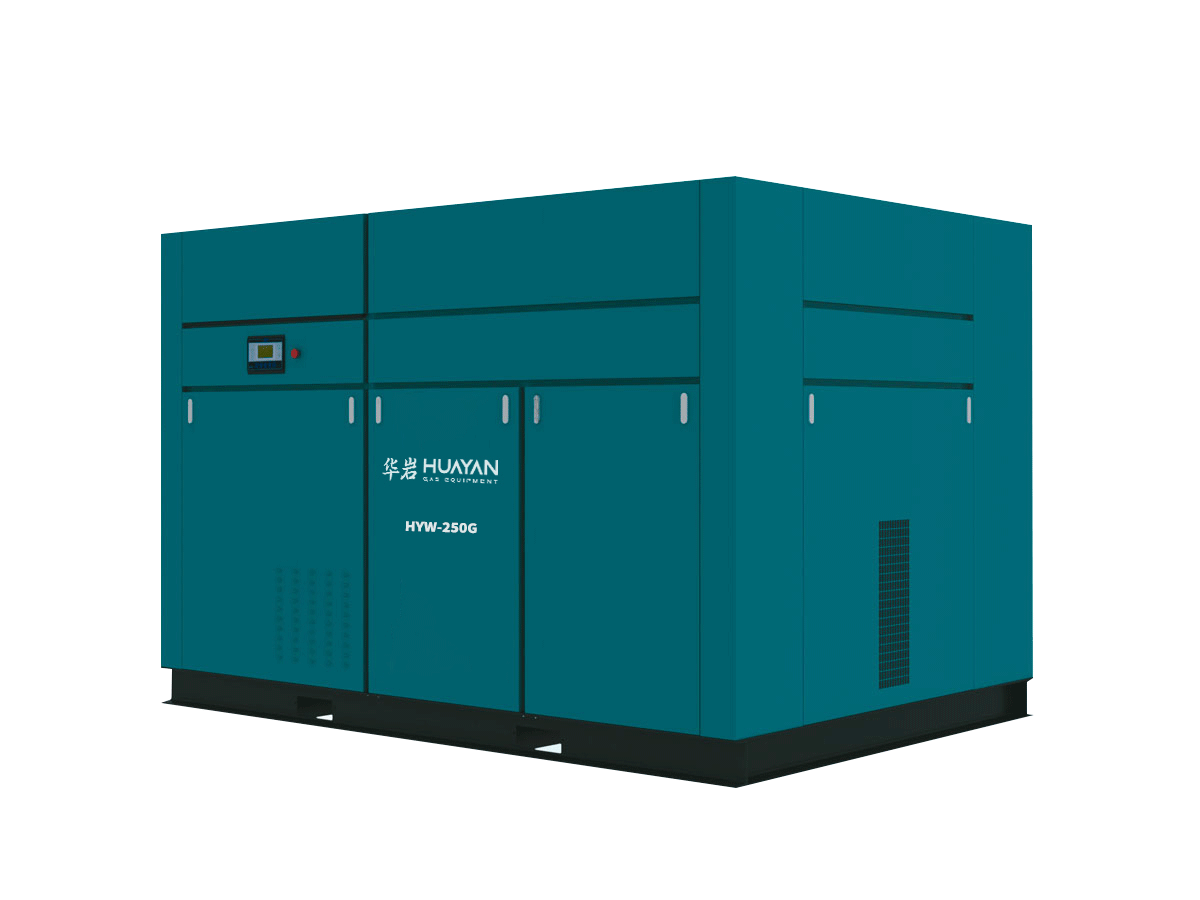

Magnet Frequency Compressor with Oil-Free Water Lubrication

Magnet Frequency Compressor with Oil-Free Water Lubrication

- Power 7.5-250kw

- Voltage 380V 3phase

- Working Pressure 7-13bar

- Flow 1m³-38m³/min

- Start Method Frequency Conversion Start

- Cooling Method From HYWV-7G to HYWV-45G Airing cooling HYWV-55G to HYWV-250G Water cooling

- Material Stainless Steel

- Deliver Time 1 Samples Within 3days

Get Free Quote

Description

Say goodbye to concerns about oil contamination in your compressed air. Our Oil-free water lubrication magnet frequency compressor boasts an oil-free design, ensuring the compressed air generated is free from oil particles. This feature makes it ideal for applications where air quality is paramount, such as pharmaceuticals, food and beverage, and electronics manufacturing. Innovating beyond traditional lubrication methods, our compressor utilizes water as a lubricant. This eliminates the need for oil and enhances cooling efficiency during the compression process.

Features & Characteristics:

- Oil-Free Operation: The compressor operates without using traditional lubricating oil, eliminating the risk of oil contamination in the compressed air or water.

- Water Lubrication System: Utilizes a water-based lubrication system to ensure smooth operation of moving parts and reduce friction and wear. This system contributes to the compressor’s environmental friendliness and minimizes the need for external lubricants.

- Magnet Frequency Drive: Incorporates a magnet frequency drive (variable frequency drive) for precise motor speed control. This feature optimizes energy efficiency by adjusting the compressor’s output to match the demand, reducing energy consumption and operating costs.

- High-Efficiency Motors: Equipped with high-efficiency electric motors to further enhance energy efficiency and reduce overall power consumption.

- Advanced Cooling System: Features an advanced cooling system, possibly using moistness or other cooling mediums, to maintain optimal operating temperatures and ensure long-term reliability.

- Compact and Space-Efficient Design: Designed to be compact and space-efficient, making it suitable for installations where space is limited. This feature is particularly beneficial in industrial settings where space constraints are common.

Main Structure: Oil-free water lubrication magnet frequency compressor

- Compressor Housing/Frame: The outer structure provides support and protection for internal components.

- Water Lubrication System: A system circulating water to lubricate moving parts and serve as a cooling agent.

- Compression Chamber: The space where air is drawn in, compressed, and discharged.

- Variable Frequency Drive (VFD): Controls the motor speed by adjusting the electrical power frequency.

- Electric Motor: Drives the compression process, often a high-efficiency electric motor.

- Magnetic Bearings: Replace traditional lubricated bearings, reducing friction and eliminating the need for oil.

- Cooling System: Maintains optimal operating temperatures using water or another cooling medium.

- Control System and Sensors: Manages compressor operation with sensors measuring parameters like pressure and temperature.

- Noise Reduction Components: Includes sound insulation materials or baffles to minimize operational noise.

Applications: Oil-free water lubrication magnet frequency compressor

- Hydroponics and Aquaponics: Adapted for use in hydroponic and aquaponic systems, where the compressor assists in aeration and nutrient distribution without introducing contaminants to the growing environment.

- Wind Tunnel Testing: Employed in wind tunnel facilities for aerodynamic testing of vehicles, aircraft, and various objects, providing precise and clean air flow during experiments.

- Data Centers: Applied in data centres for cooling systems and equipment that require compressed air, ensuring the reliability and efficiency of data processing infrastructure.

- Microelectronics Manufacturing: Utilized in the production of microelectronics, including tasks such as wafer handling and chip manufacturing, where the absence of oil is crucial for the integrity of electronic components.

- Small-Scale Industry and Workshops: Suitable for small-scale industries and workshops where a compact, efficient, and oil-free compressor is needed for various applications, such as powering air tools and pneumatic machinery.