CO₂ Reciprocating Compressor

CO₂ Reciprocating Compressor

Get Free Quote

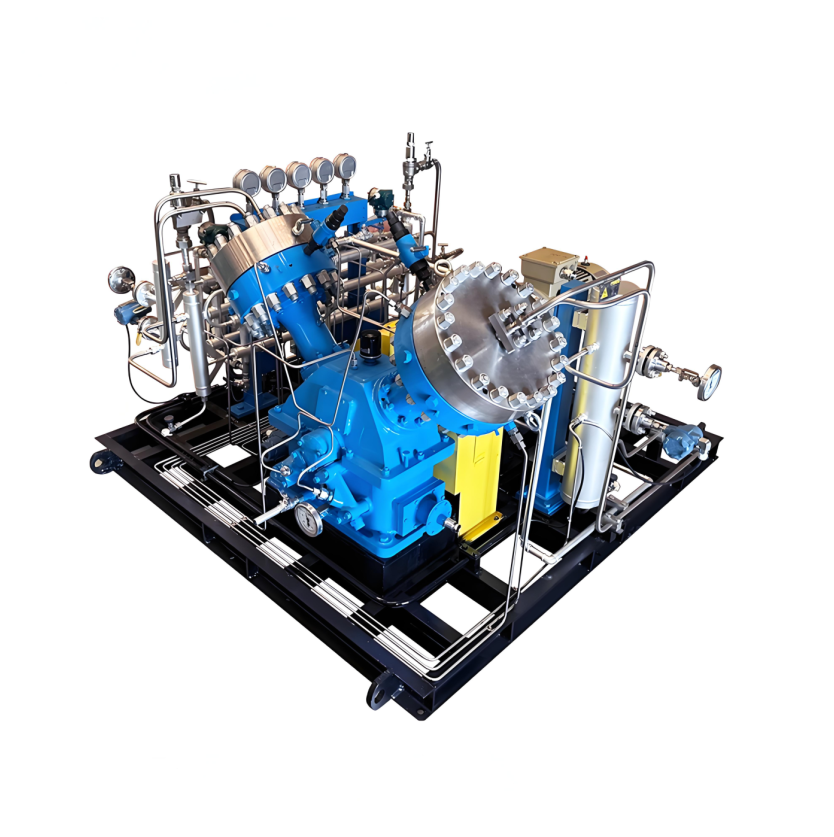

The CO₂ reciprocating compressor is a specially engineered oil-free compression system designed for demanding high-pressure CO₂ environments. Built on advanced reciprocating technology and integrated with precision engineering, this plug-and-play skid-mounted unit offers a compact yet powerful solution for industries requiring clean, efficient, and reliable CO₂ gas handling.

Features

- Oil-Free Compression: Eliminates risk of oil contamination, ideal for food-grade and environmental applications.

- Horizontal, Low-Speed Design: Long-stroke cylinders reduce wear and extend component lifespan.

- Stainless Steel Cylinders: Corrosion-resistant with nickel-plated interiors and forced lubrication, ensuring long-term performance even in moist CO₂ conditions.

- Flexible Cooling Options: Choose from water-cooled, air-cooled, or hybrid systems to match site conditions.

- Fully Integrated System: Compressor, motor, cooling system, lubrication, and PLC control are housed within a single modular skid, simplifying installation and operation.

- Configurable Design: Available in Z, D, or V configurations with customizable displacement, pressure ratings, and motor/control brands.

Performance Advantages

- Energy Efficient & Quiet Operation: Engineered for low energy consumption, minimal vibration, and reduced noise levels.

- Durable Components: Fitted with premium valve plates and piston rings from Austrian brand Hoerbiger, with a service life exceeding 8,000 hours.

- Intelligent Control System: Equipped with Siemens PLC and ABB soft starter or inverter. Supports auto shutdown, fault alarms, and seasonal performance adaptation.

- Variable Frequency Drive (VFD) Ready: Allows stepless capacity modulation to meet dynamic process needs.

Application Scenarios

Ideal for a wide range of CO₂-intensive processes, including:

- Brewery CO₂ Recovery

- Wastewater Treatment

- Supercritical CO₂ Extraction

- Dry Ice Production

- Environmental and Food Industries

With flow capacities ranging from 70 to 4000 kg/h, this compressor series supports both small-scale and large-scale operations.

Safety & Maintenance Guidelines

- Designed to meet the specific safety requirements of high-pressure CO₂ systems.

- Static pressure after shutdown must remain below 100 bar.

- Always follow the manufacturer’s manual during maintenance to avoid dry friction and ensure safe operation.

Custom Engineering Services

- Each compressor can be tailored to fit your process requirements:

- Adjustable displacement and pressure ranges

- Custom motor brands and electrical configurations

- Explosion-proof and remote monitoring options available

- Optional soundproof enclosure for noise-sensitive environments