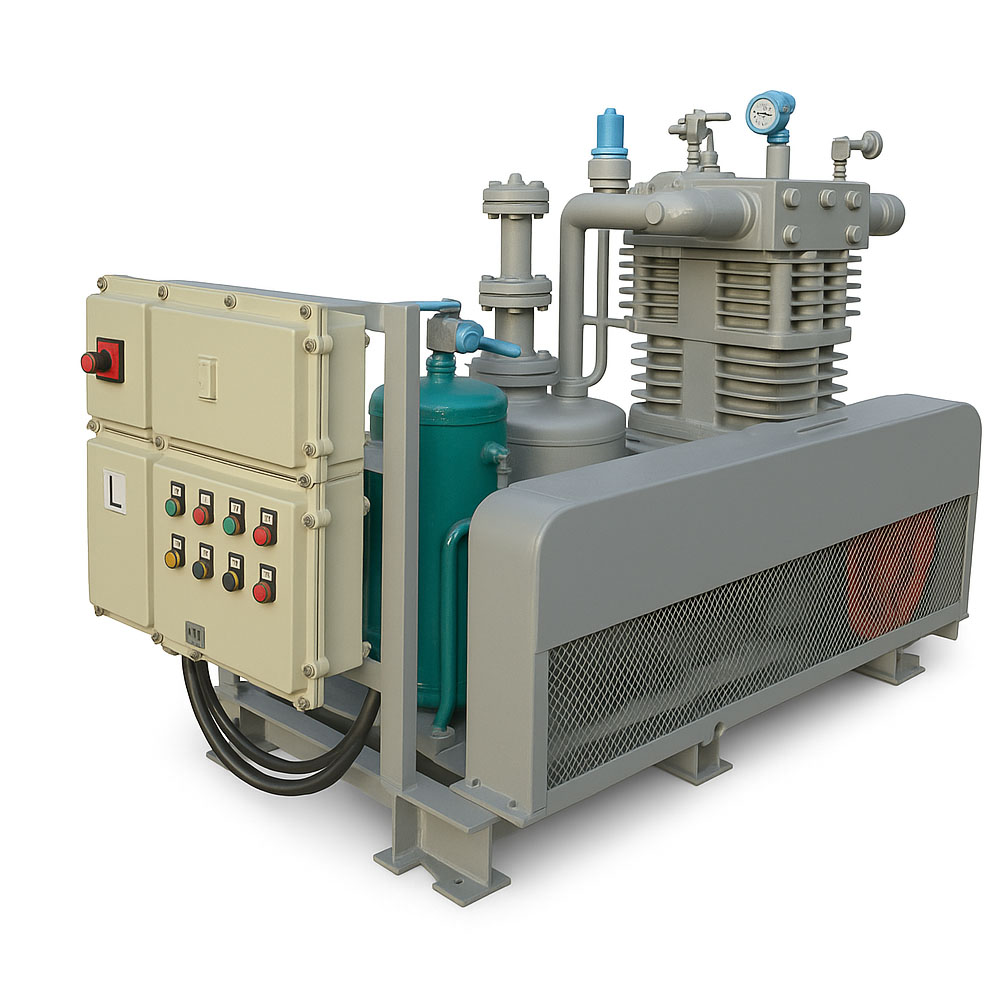

CNG Reciprocating Compressor

CNG Reciprocating Compressor

- Compressor Type: CNG Reciprocating Piston Compressor

- Models Available: Z-type, V-type, D-type

- Suction Pressure Range: 0.02 – 4 MPa

- Discharge Pressure: Up to 25 MPa

- Flow Rate: 60 Nm³/h – 17,000 Nm³/h

- Motor Power: 18.5 kW – 350 kW

- Voltage: 220V / 380V / 400V / 415V / 50–60Hz (Customizable)

- Noise Level: <80 dB

- Crankshaft Speed: 350 – 420 rpm

- Cooling Options: Water-cooled or air-cooled

- Configuration: Single-stage, two-stage, multi-stage; single-cylinder to multi-cylinder

- Certifications: ISO9001, CE Certified

Features & Advantages:

1. High Performance & Stability

Our CNG reciprocating compressors deliver consistent performance even under variable conditions. Designed to operate continuously in demanding environments, they ensure safety and reliability throughout the compression process.

2.Wide Pressure Adaptability

With a maximum discharge pressure of 25 MPa, the compressor easily meets the requirements of CNG filling, storage, and transportation systems.

3. Energy-Efficient Operation

Utilizing advanced energy-saving technologies, our units reduce power consumption while maintaining high compression output, lowering total cost of ownership.

4. Corrosion & Leak Resistance

With optional corrosion-resistant materials and superior sealing performance, the compressors ensure no contamination of the compressed natural gas and deliver clean, safe energy.

5. Modular Design Options

Available in fixed, skid-mounted, and mobile types, the compressor units are adaptable to various site layouts and installation requirements. Customized designs are available based on project scale and application.

Integrated Compressor System

Each CNG reciprocating compressor unit includes:

- Heavy-duty piston compressor block

- Energy-efficient motor

- Coupling and flywheel assembly

- Advanced piping and cooling systems

- Smart control panel (PLC/HMI optional)

- Auxiliary accessories for optimized performance

Applications:

- CNG Standard & Daughter Stations

- Industrial Natural Gas Distribution

- Biogas Upgrading Systems

- Pipeline Boosting & Storage

- Vehicle Refueling Infrastructure

These compressors integrate seamlessly with gas purification, pressure control, storage cylinders, and safety systems to form a complete CNG fueling solution.

Why Choose Our CNG Reciprocating Compressor?

- High-pressure capability up to 25 MPa

- Reliable long-term operation

- Custom-built for your specific project needs

- Wide range of flow and power options

- Easy maintenance with low downtime

- ISO and CE certified quality assurance

CNG Reciprocating Compressor-Parameter Table

|

Number |

Model |

Flow-rate(Nm3/h) |

Inlet pressure(Mpa) |

Exhaust pressure(Mpa) |

Medium |

Motor power(kw) |

Overall dimensions(mm) |

|

1 |

ZW-0.5/15 |

24 |

Normal pressure |

1.5 |

Hydrogen |

7.5 |

1600*1300*1250 |

|

2 |

ZW-0.16/30-50 |

240 |

3 |

5 |

Hydrogen |

11 |

1850*1300*1200 |

|

3 |

ZW-0.45/22-26 |

480 |

2.2 |

2.6 |

Hydrogen |

11 |

1850*1300*1200 |

|

4 |

ZW-0.36 /10-26 |

200 |

1 |

2.6 |

Hydrogen |

18.5 |

2000*1350*1300 |

|

5 |

ZW-1.2/30 |

60 |

Normal pressure |

3 |

Hydrogen |

18.5 |

2000*1350*1300 |

|

6 |

ZW-1.0/1.0-15 |

100 |

0.1 |

1.5 |

Hydrogen |

18.5 |

2000*1350*1300 |

|

7 |

ZW-0.28/8-50 |

120 |

0.8 |

5 |

Hydrogen |

18.5 |

2100*1350*1150 |

|

8 |

ZW-0.3/10-40 |

150 |

1 |

4 |

Hydrogen |

22 |

1900*1200*1420 |

|

9 |

ZW-0.65/8-22 |

300 |

0.8 |

2.2 |

Hydrogen |

22 |

1900*1200*1420 |

|

10 |

ZW-0.65/8-25 |

300 |

0.8 |

25 |

Hydrogen |

22 |

1900*1200*1420 |

|

11 |

ZW-0.4/(9-10)-35 |

180 |

0.9-1 |

3.5 |

Hydrogen |

22 |

1900*1200*1420 |

|

12 |

ZW-0.8/(9-10)-25 |

400 |

0.9-1 |

2.5 |

Hydrogen |

30 |

1900*1200*1420 |

|

13 |

DW-2.5/0.5-17 |

200 |

0.05 |

1.7 |

Hydrogen |

30 |

2200*2100*1250 |

|

14 |

ZW-0.4/(22-25)-60 |

350 |

2.2-2.5 |

6 |

Hydrogen |

30 |

2000*1600*1200 |

|

15 |

DW-1.35/21-26 |

1500 |

2.1 |

2.6 |

Hydrogen |

30 |

2000*1600*1200 |

|

16 |

ZW-0.5/(25-31)-43.5 |

720 |

2.5-3.1 |

4.35 |

Hydrogen |

30 |

2200*2100*1250 |

|

17 |

DW-3.4/0.5-17 |

260 |

0.05 |

1.7 |

Hydrogen |

37 |

2200*2100*1250 |

|

18 |

DW-1.0/7-25 |

400 |

0.7 |

2.5 |

Hydrogen |

37 |

2200*2100*1250 |

|

19 |

DW-5.0/8-10 |

2280 |

0.8 |

1 |

Hydrogen |

37 |

2200*2100*1250 |

|

20 |

DW-1.7/5-15 |

510 |

0.5 |

1.5 |

Hydrogen |

37 |

2200*2100*1250 |

|

21 |

DW-5.0/-7 |

260 |

Normal pressure |

0.7 |

Hydrogen |

37 |

2200*2100*1250 |

|

22 |

DW-3.8/1-7 |

360 |

0.1 |

0.7 |

Hydrogen |

37 |

2200*2100*1250 |

|

23 |

DW-6.5/8 |

330 |

Normal pressure |

0.8 |

Hydrogen |

45 |

2500*2100*1400 |

|

24 |

DW-5.0/8-10 |

2280 |

0.8 |

1 |

Hydrogen |

45 |

2500*2100*1400 |

|

25 |

DW-8.4/6 |

500 |

Normal pressure |

0.6 |

Hydrogen |

55 |

2500*2100*1400 |

|

26 |

DW-0.7/(20-23)-60 |

840 |

2-2.3 |

6 |

Hydrogen |

55 |

2500*2100*1400 |

|

27 |

DW-1.8/47-57 |

4380 |

4.7 |

5.7 |

Hydrogen |

75 |

2500*2100*1400 |

|

28 |

VW-5.8/0.7-15 |

510 |

0.07 |

1.5 |

Hydrogen |

75 |

2500*2100*1400 |

|

29 |

DW-10/7 |

510 |

Normal pressure |

0.7 |

Hydrogen |

75 |

2500*2100*1400 |

|

30 |

VW-4.9/2-20 |

750 |

0.2 |

2 |

Hydrogen |

90 |

2800*2100*1400 |

|

31 |

DW-1.8/15-40 |

1500 |

1.5 |

4 |

Hydrogen |

90 |

2800*2100*1400 |

|

32 |

DW-5/25-30 |

7000 |

2.5 |

3 |

Hydrogen |

90 |

2800*2100*1400 |

|

33 |

DW-0.9/20-80 |

1000 |

2 |

8 |

Hydrogen |

90 |

2800*2100*1400 |

|

34 |

DW-25/3.5-4.5 |

5700 |

0.35 |

0.45 |

Hydrogen |

90 |

2800*2100*1400 |

|

35 |

DW-1.5/(8-12)-50 |

800 |

0.8-1.2 |

5 |

Hydrogen |

90 |

2800*2100*1400 |

|

36 |

DW-15/7 |

780 |

Normal pressure |

0.7 |

Hydrogen |

90 |

2800*2100*1400 |

|

37 |

DW-5.5/2-20 |

840 |

0.2 |

2 |

Hydrogen |

110 |

3400*2200*1300 |

|

38 |

DW-11/0.5-13 |

840 |

0.05 |

1.3 |

Hydrogen |

110 |

3400*2200*1300 |

|

39 |

DW-14.5/0.04-20 |

780 |

0.004 |

2 |

Hydrogen |

132 |

4300*2900*1700 |

|

40 |

DW-2.5/10-40 |

1400 |

1 |

4 |

Hydrogen |

132 |

4200*2900*1700 |

|

41 |

DW-16/0.8-8 |

2460 |

0.08 |

0.8 |

Hydrogen |

160 |

4800*3100*1800 |

|

42 |

DW-1.3/20-150 |

1400 |

2 |

15 |

Hydrogen |

185 |

5000*3100*1800 |

|

43 |

DW-16/2-20 |

1500 |

0.2 |

2 |

Hydrogen |

28 |

6500*3600*1800 |