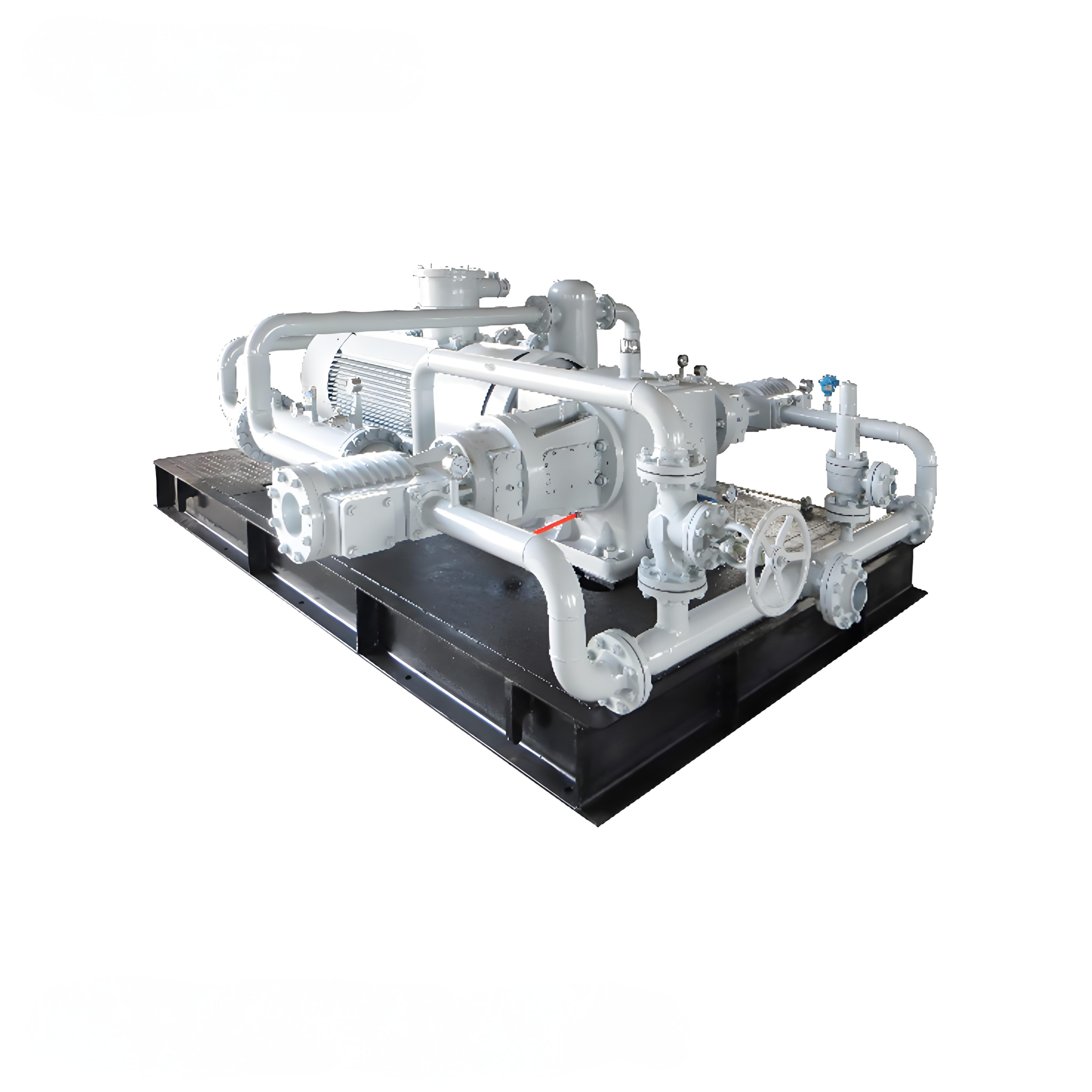

C4H10 Compressor

C4H10 Compressor

- Applicable Gas: Isobutane (C4H10, R600a)

- Compressor Design: Oil-lubricated reciprocating piston type

- Power Range: 37 kW to 110 kW (custom-tailored options available)

- Flow Capacity 6 Nm³/min to 20 Nm³/min

- Inlet Pressure: 0.2 bar – 1 bar

- Discharge Pressure: Up to 80 bar

- Cooling Method: Air-cooled or water-cooled configuration

- Drive Mechanism: Belt-driven or direct coupling

- Control System: Intelligent PLC or HMI interface with real-time pressure & temperature monitoring, fault diagnostics

- Lubrication System: Forced oil circulation with low-pressure shutdown protection

- Core Materials: High-strength alloy steel for cylinder blocks and valve assemblies

Why Choose Our C4H10 Compressor?

Optimized for High Pressure

Safely compresses isobutane up to 80 bar, ideal for applications such as liquefaction, storage, or filling.

Industrial-Grade Durability

Rugged construction with a reinforced skid base ensures long-term stability and low vibration, even under continuous operation.

Superior Thermal Management

Optional air or water cooling allows the unit to adapt to various working environments and thermal loads.

Smart Automation

Integrated control system enables remote operation, real-time monitoring, automatic shutdowns, and data logging.

Energy Efficiency

High-performance electric motors paired with precision control lower power consumption and reduce long-term operational costs.

Flexible Customization

We support tailored configurations including inlet/outlet port sizes, motor voltage, pressure ratings, and installation options.

Pros & Considerations:

Advantages:

- Designed for safe operation with flammable gases like C4H10

- Built to perform under high pressure with customizable features

- Automated control minimizes human error and improves efficiency

- Long service life with minimal downtime thanks to wear-resistant materials

Considerations:

Requires stable access to water or air cooling sources

Higher initial setup cost than low-pressure alternatives

Professional installation and periodic oil maintenance are essential for optimal performance

Applications:

This C4H10 compressor is widely used in sectors like:

- Aerosol and refrigerant filling

- Petrochemical and gas recovery

- Isobutane liquefaction processes

- Industrial gas storage and transportation systems