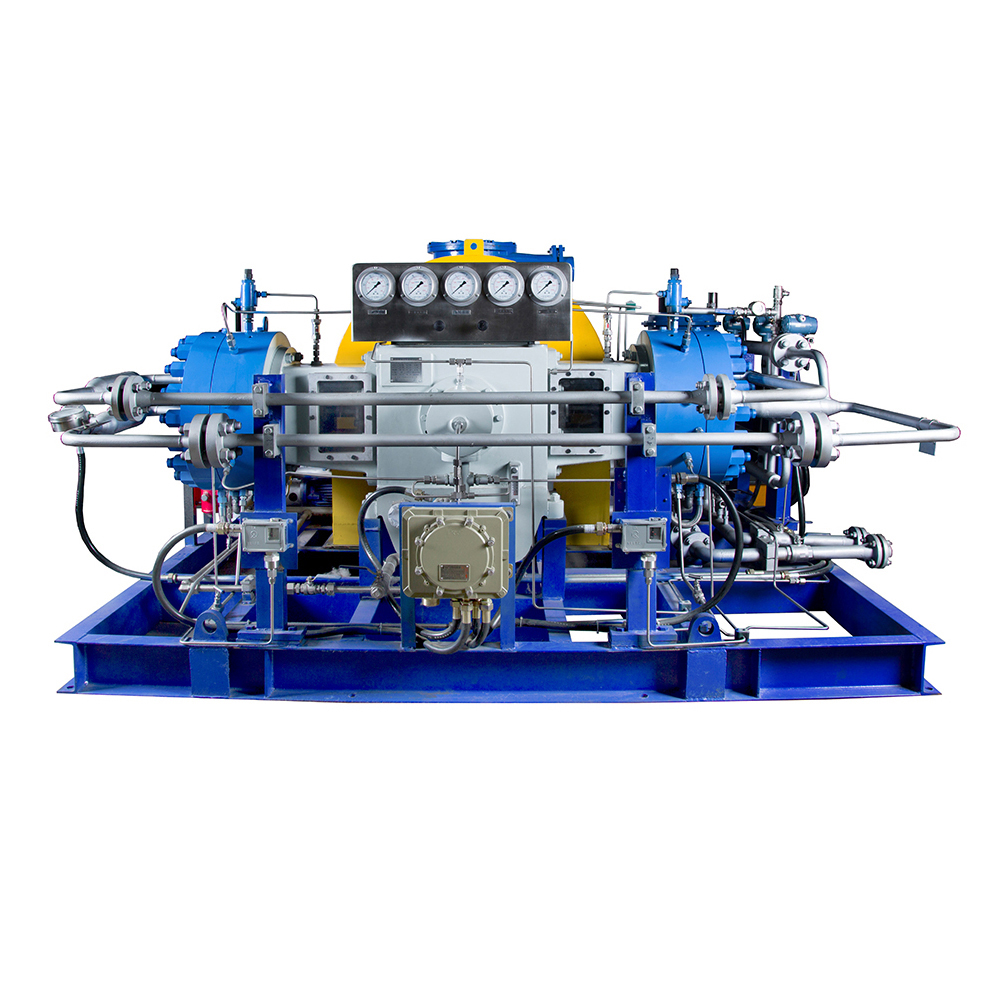

Argon Diaphragm Compressor

Argon Diaphragm Compressor

- Gas Type: Argon (Ar)

- Compression Stages: 1–4 stages

- Inlet Pressure: 0.1–30 bar

- Discharge Pressure: Up to 3000 bar

- Flow Rate: 1 – 100 Nm³/h (customizable)

- Cooling Type: Air-cooled / Water-cooled

- Lubrication: Oil-free

- Drive Method: Electric motor / Explosion-proof motor

- Diaphragm Material: Stainless Steel / Hastelloy

- Sealing Type: Double-layer diaphragm with alarm monitoring

- Installation: Skid-mounted, plug & play

An argon diaphragm compressor is a specialized high-pressure gas compressor designed to compress argon gas without any risk of oil or particulate contamination. By using a metal diaphragm isolation system, the compressor ensures complete separation between the gas and mechanical parts, making it ideal for handling high-purity and rare gases in demanding industrial environments.

Product Overview

Our argon diaphragm compressors are engineered to deliver safe, efficient, and leak-free compression of argon gas up to pressures of 100–3000 bar (1450–43,500 psi). These units are widely used in laboratories, semiconductor manufacturing, gas recovery systems, nuclear energy, welding operations, and cylinder filling stations where gas purity and system reliability are critical.

Working Principle

A diaphragm compressor uses a reciprocating piston to move a flexible metal diaphragm, which compresses the gas inside a sealed compression chamber. The diaphragm acts as a physical barrier that prevents direct contact between the gas and any lubricants or mechanical components.

benefits of this design:

100% oil-free compression

Zero metal-to-gas contamination

Leak-tight gas compression for rare or expensive gases like argon, helium, and hydrogen

Features

Oil-Free Design: Completely dry compression system, ideal for ultra-pure gas applications.

High Pressure Capability: Single-stage or multi-stage configurations available for pressures up to 3000 bar.

Corrosion-Resistant Materials: Wetted parts are made of stainless steel, Hastelloy, or Inconel for aggressive or corrosive gases.

Gas Purity Assurance: Diaphragm barrier ensures no contamination or loss of purity.

Compact & Quiet Operation: Compact skid-mounted design with optional noise reduction system.

Long Diaphragm Life: Advanced diaphragm structure and monitoring system to extend service intervals.

Typical Applications

- Argon Cylinder Filling Stations

- Semiconductor and Electronics Manufacturing

- Shielding Gas Supply for TIG/MIG Welding

- Rare Gas Recovery and Recycling

- Nuclear and Research Laboratories

- Cryogenic Systems & Gas Booster Stations

Customization Options

We offer full customization for your argon diaphragm compressor project:

- Custom flow rate and pressure requirements

- Explosion-proof and ATEX-compliant models

- PLC touch screen interface for monitoring and remote control

- Gas purity certification and leak detection systems

- Integrated gas purification and buffer tank solutions

Service & Support

- Pre-Sales Consultation: Professional advice and proposal design tailored to your gas system requirements

- Global Shipping & Onsite Installation

- User Training & Commissioning Support

- Spare Parts Supply & Maintenance Contracts

- 24/7 After-Sales Support & Troubleshooting

Why Choose Our Argon Diaphragm Compressors?

With years of experience in high-purity gas compression, we deliver robust, safe, and contamination-free solutions trusted by customers in more than 60 countries. Whether you are compressing argon for laboratory use or industrial-scale cylinder filling, our systems offer unmatched reliability and performance.