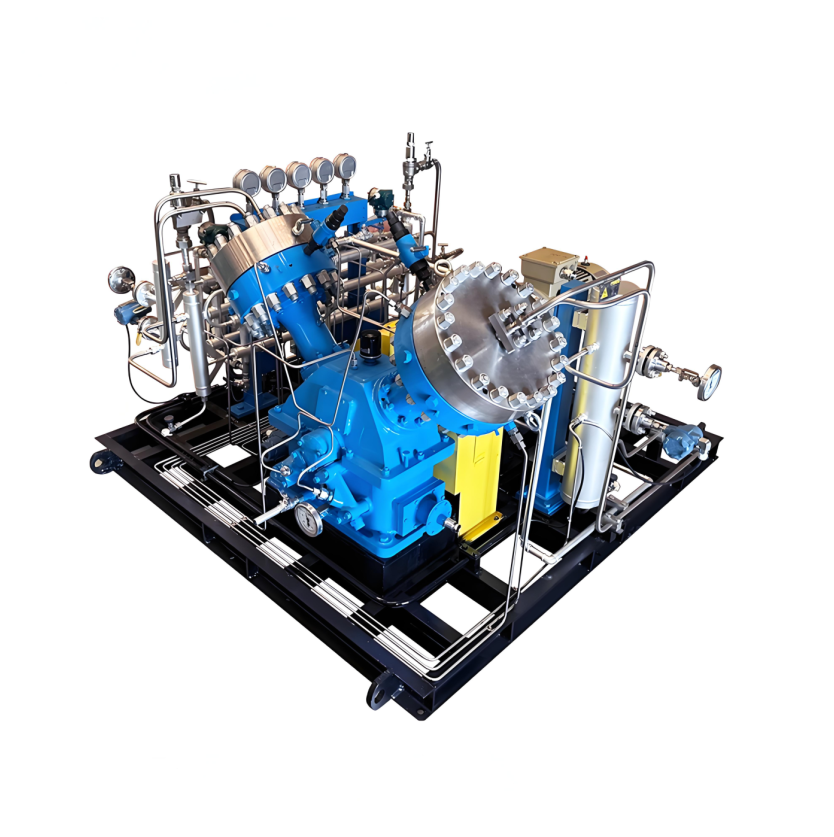

O2 Reciprocating Compressor

O2 Reciprocating Compressor

- Flow Rate: 10 Nm³/h – 2500 Nm³/h

- Discharge Pressure: 5 bar – 30 bar (customizable)

- Inlet Pressure: Atmospheric or up to 3 bar

- Cooling Type: Air-cooled / Water-cooled

- Compression Stages: 2 to 4 stages

- Lubrication: Oil-Free, PTFE piston rings

- Motor Power: 5.5 kW – 110 kW

- Drive Type: Electric motor (belt or direct)

- Noise Level: < 75 dB(A)

Overview

The O2 reciprocating compressor is a high-efficiency, oil-free compression system designed specifically for the safe and reliable compression of oxygen gas. Engineered to meet the stringent demands of medical, industrial, and high-purity applications, this compressor ensures contamination-free operation, excellent gas purity, and long service life.

Features

- Oil-Free Design

Completely oil-free compression chambers prevent hydrocarbon contamination, ensuring the oxygen remains clean and dry — ideal for applications with high purity requirements such as medical oxygen supply, gas filling stations, and metallurgy.

- Multi-Stage Compression

Most units adopt two- to four-stage compression structures to effectively reduce temperature rise and optimize energy efficiency while achieving required discharge pressures (typically up to 5–30 bar or customized higher pressures).

- Low Discharge Temperature

Efficient inter-stage cooling systems (water or air-cooled) minimize heat buildup, extending component lifespan and enhancing system reliability.

- High Gas Purity Handling

Compatible with 99.5% and higher purity oxygen; tailored internal treatments and surface coatings ensure safe handling of oxidizing gases.

- Explosion-Proof and Oxygen-Compatible Materials

Constructed with non-sparking materials such as stainless steel, copper alloy, or anodized aluminum, minimizing fire hazards in oxygen-rich environments.

Applications

- Medical & Healthcare

Used in oxygen cylinder filling systems, PSA oxygen generator booster systems, and centralized oxygen supply stations.

- Metallurgical Processing

Supplies pressurized oxygen for steel refining, non-ferrous metal smelting, and glass manufacturing processes.

- Wastewater Treatment

Oxygen aeration and ozone generation processes require clean and dry compressed oxygen.

- Environmental Protection

Oxygen compression in bio-reactors and ozone generation systems.

- Gas Filling Plants

Used for bottling of medical or industrial oxygen in high-pressure cylinders.

Safety Features

- Automatic Overload Protection

- Inter-stage Pressure & Temperature Monitoring

- Anti-corrosive Internal Components

- Explosion-Proof Electric Motors (Optional)

- Inlet Filters & Check Valves

Advantages

- 100% Oil-Free – No contamination risk

- High Purity Oxygen Compatibility

- Compact Structure, Easy Maintenance

- Low Energy Consumption

- Robust, Long-Life Components

- CE/ISO/ASME Compliant Options

Customization Options

- Inlet & outlet pressure levels

- Skid-mounted or containerized system

- Explosion-proof control panels

- PLC control system with remote monitoring

- Integration with PSA or LOX storage systems

Why Choose Our O2 Reciprocating Compressors?

We specialize in custom-engineered oxygen compression solutions for global customers across sectors. With advanced sealing technologies, optimized piston and cylinder materials, and modular system design, our O2 reciprocating compressors combine safety, performance, and adaptability — ensuring smooth operation even in demanding environments.