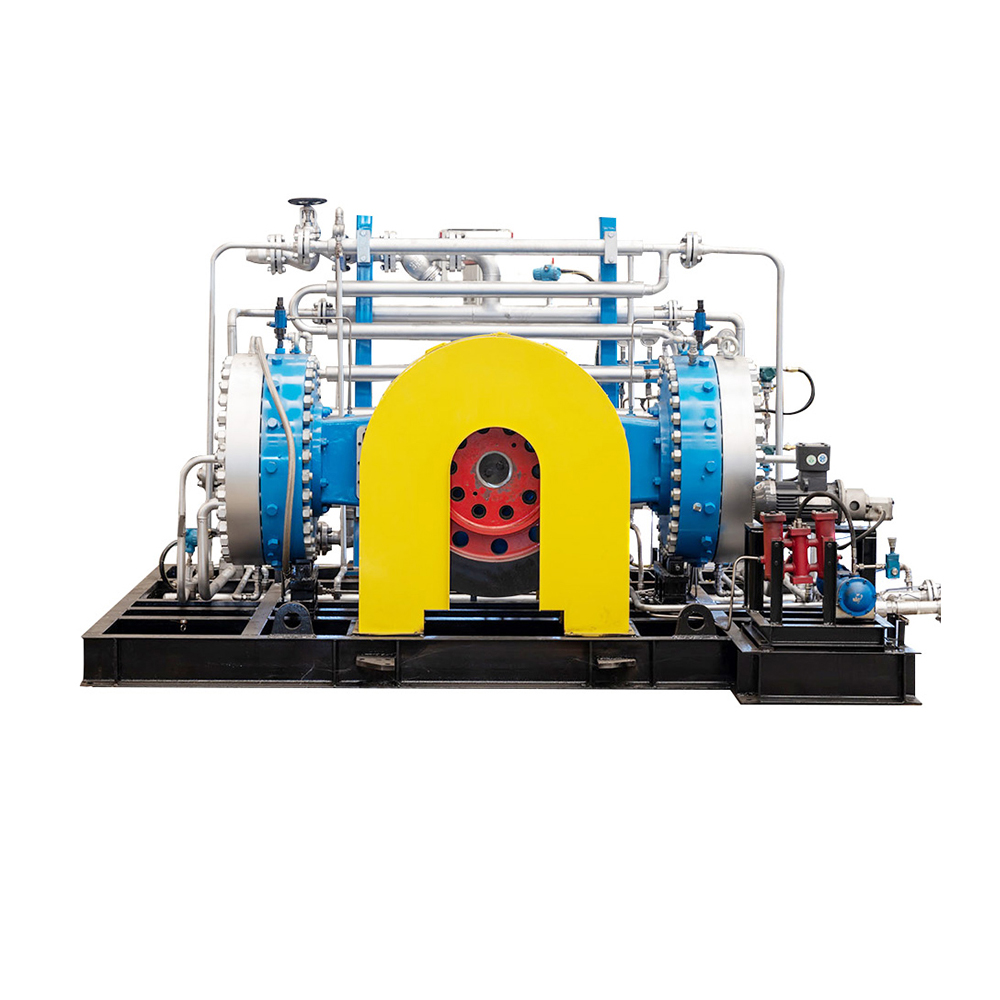

Diaphragm Compressor

Diaphragm Compressor

- Compressor Type: iaphragm Compressor

- Model: GD Series

- Piston Stroke: 130 mm – 210 mm

- Flow Capacity: 30 Nm³/h – 2000 Nm³/h (customizable)

- Voltage: 380V / 50Hz (customizable)

- Maximum Outlet Pressurev Up to 100 MPa (customizable)

- Motor Power: 30 kW – 185 kW (customizable)

- Noise Level: < 80 dB

- Crankshaft Speed: 350 – 420 rpm

- Certificate: ISO9001, CE certificate, etc.

Diaphragm compressors are highly reliable machines designed for the delivery and pressurization of a wide variety of gases. These compressors are especially suitable for applications requiring clean, contamination-free gas compression, thanks to their superior cylinder sealing. Diaphragm compressors can also serve as booster compressors following oil-free lubricated compressors, making them ideal for critical industrial and laboratory uses where gas purity is essential.

Advantages of Diaphragm Compressors:

Diaphragm compressors offer high design outlet pressure and exceptional gas purity, as there is no oil contamination during compression. With superior sealing performance and the option to use corrosion-resistant materials, diaphragm compressors are ideal for handling a wide variety of gases in demanding industrial and laboratory environments.

What Are Diaphragm Compressors? Overview, Features, and Classifications

Diaphragm compressors are a type of positive displacement compressor known for their unique structural design and exceptional gas purity performance. As one of the most advanced gas compression technologies, diaphragm compressors ensure that the gas is completely isolated from lubricants and contaminants throughout the compression process. This makes them the preferred solution for compressing gases where purity and safety are critical.

Unlike traditional piston compressors, diaphragm compressors use a flexible diaphragm to compress gas, eliminating the risk of secondary pollution. They offer a high compression ratio, superior sealing capability, and reliable protection for the compressed gas. As a result, diaphragm compressors are ideal for handling high-purity gases, rare and precious gases, flammable and explosive gases, toxic and hazardous gases, corrosive gases, and high-pressure applications.

Due to their outstanding performance, diaphragm compressors are widely recognized and recommended internationally for compressing oxygen, hydrogen, helium, nitrogen, and other sensitive gases.

Classification of Diaphragm Compressors

Why Choose Diaphragm Compressors?

- Zero contamination: No oil or solid impurity contact with the gas.

- Excellent sealing: Ensures gas purity and safety.

- High compression ratio: Suitable for high-pressure requirements.

- Wide application: Perfect for industries requiring strict gas purity—such as chemical processing, medical gas supply, electronics, and aerospace.

GD SERIES DIAPHRAGM COMPRESSOR-PARAMETER TA

| GD series diaphragm compressor parameter table | ||||||||

| Model | Cooling water (L/h) |

Flow (Nm³/h) |

Inlet pressure (MPa) | Outlet pressure (MPa) |

Dimensions L×W×H(mm) | Weight (Kg) |

Motor Power (kW) | |

| 1 | GD-120/4-80 | 3000 | 120 | 0.4 | 8.0 | 3000×1600×1400 | 4000 | 30 |

| 2 | GD-130/0.98-11 | 3000 | 130 | 0.098 | 1.1 | 3000×1800×1600 | 4000 | 30 |

| 3 | GD-150/2-20 | 3000 | 150 | 0.2 | 2.0 | 3000×1800×1600 | 4000 | 37 |

| 4 | GD-100/0.1-5 | 4000 | 100 | 0.01 | 0.5 | 2800×1500×1500 | 3000 | 18.5 |

| 5 | GD-100/5.5-200 | 5000 | 100 | 0.55 | 20 | 3200×2000×1600 | 4500 | 45 |

| 6 | GD-80/0.12-4 | 5000 | 80 | 0.012 | 0.4 | 2800×1600× 1500 | 3800 | 15 |

| 7 | GD-60/0.3-6 | 4000 | 60 | 0.03 | 0.6 | 2800×1600×1500 | 4000 | 15 |

| 8 | GD-70/0.1-8 | 3800 | 70 | 0.01 | 0.8 | 3000×1600×1250 | 5000 | 18.5 |

| 9 | GD-40/0.02-160 | 5000 | 40 | 0.02 | 16 | 2800×1460×1530 | 3000 | 22 |

| 10 | GD-100/0.5-6 | 2000 | 100 | 0.05 | 0.6 | 3000×2000×1560 | 6000 | 18.5 |

| 11 | GD-36/1-150 | 4000 | 36 | 0.1 | 15 | 3000×1500×1500 | 4000 | 45 |

| 12 | GD-35/0.7-300 | 4000 | 35 | 0.07 | 30 | 3000×1600×1500 | 4000 | 22 |

| 13 | GD-500/15-35 | 4500 | 500 | 1.5 | 3.5 | 3000×2000×1700 | 4000 | 45 |

| 14 | GD-150/15-210 | 4500 | 150 | 1.5 | 21 | 3200×1700×1600 | 4000 | 45 |

| 15 | GD-120/8-220 | 4500 | 120 | 0.8 | 22 | 3200×1700×1600 | 3800 | 45 |

| 16 | GD-100/9 | 4500 | 100 | 0.0 | 0.9 | 3200×1700×1800 | 4500 | 22 |

| 17 | GD-100/1.5-150 | 4500 | 100 | 0.15 | 15 | 3200×1700×1800 | 4500 | 45 |

| 18 | GD-40/30 | 4500 | 40 | 0.0 | 3.0 | 3200×1700×1800 | 4000 | 18.5 |

| 19 | GD-200/10-15-90 | 4500 | 200 | 1.0-1.5 | 9.0 | 3200×1800×1600 | 4000 | 37 |

| 20 | GD-100/7-150 | 4000 | 100 | 0.7 | 15 | 3000×1800× 1600 | 4000 | 55 |

| 21 | GD-25/-0.1-47 | 4000 | 25 | -0.01 | 4.7 | 3000×1800×1600 | 4000 | 15 |

| 22 | GD-45/0.5-100 | 4000 | 45 | 0.05 | 10 | 3000×1800×1600 | 4000 | 30 |

| 23 | GD-30/0.1-160 | 4000 | 30 | 0.01 | 16 | 3000×1800×1600 | 4000 | 18.5 |

| 24 | GD-120/2.5-70 | 4000 | 120 | 0.25 | 7.0 | 3000×1800×1600 | 4000 | 37 |

| 25 | GD-135/10-210 | 4000 | 135 | 1.0 | 21 | 3000×1600×1400 | 4000 | 37 |

| 26 | GD-60/40-350 | 4500 | 60 | 4.0 | 35 | 3000×1800×1600 | 4000 | 30 |

| 27 | GD-95/10-350 | 4000 | 95 | 1.0 | 35 | 3000×1600×1400 | 4000 | 37 |

| 28 | GD-220/11-90 | 4000 | 220 | 1.1 | 9.0 | 3000×1800×1600 | 4000 | 37 |

| 29 | GD-300/15-220 | 4500 | 300 | 1.5 | 22 | 3600×2200×1700 | 5000 | 75 |

| 30 | GD-300/13-210 | 5000 | 300 | 1.3 | 21 | 3500×2300×1800 | 6000 | 75 |

| 31 | GD-120/12-350 | 6500 | 120 | 1.2 | 35 | 3500×2300×1600 | 8500 | 45 |

| 32 | GD-165/10-250 | 8000 | 165 | 1.0 | 25 | 3500×2300×1500 | 8500 | 55 |

| 33 | GD-120/8-350 | 6500 | 120 | 0.8 | 35 | 3500×2300×1600 | 8500 | 45 |

| 34 | GD-800/210-320 | 8000 | 800 | 21 | 32 | 3500×2300×1500 | 8500 | 37 |

| 35 | GD-420/8-39 | 6500 | 420 | 0.8 | 3.9 | 3600×2500×1700 | 6000 | 75 |

| 36 | GD-370/20-200 | 4500 | 370 | 2.0 | 20 | 3600×2200×1700 | 5000 | 75 |

| 37 | GD-350/18-210 | 4500 | 350 | 1.8 | 21 | 3600×2200×1700 | 5000 | 75 |

| 38 | GD-300/8-120 | 4500 | 300 | 0.8 | 12 | 3600×2200×1700 | 5000 | 75 |

| 39 | GD-308/4 | 10000 | 308 | 0 | 0.4 | 4200×3200×2600 | 10000 | 55 |

| 40 | GD-180/8.5 | 5000 | 180 | 0 | 0.85 | 4200×3200×2600 | 10000 | 55 |