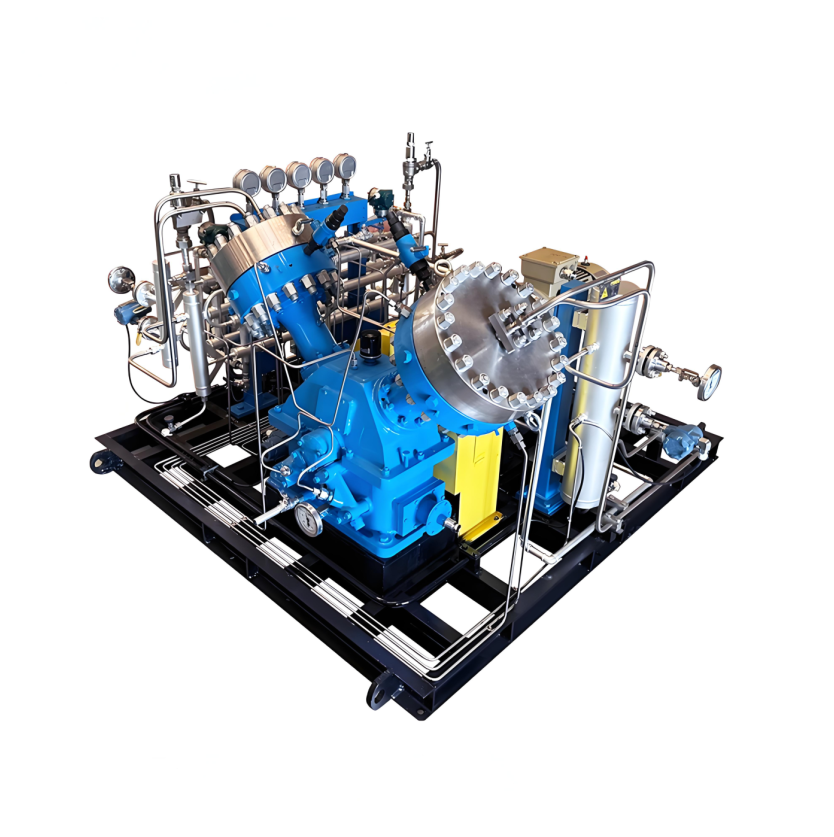

CO Reciprocating Compressor

CO Reciprocating Compressor

- Inlet Pressure: 0.1 – 4 MPa

- Discharge Pressure: Up to 25 MPa

- Flow Rate: 60 – 17,000 Nm³/h

- Power Range: 18.5 kW – 350 kW

- Crankshaft Speed: 350 – 420 rpm

- Noise Level: <80 dB

- Voltage/Frequency: 220V–415V, 50/60Hz (customized)

- Cooling Method: Air-cooled / Water-cooled

- Installation Type: Stationary / Mobile / Skid-mounted

Get Free Quote

Core Features

- Wide Pressure Capability:Supports single-stage and multi-stage configurations with discharge pressures up to 25 MPa or higher, suitable for CO₂, H₂, CH₄, and process gases.

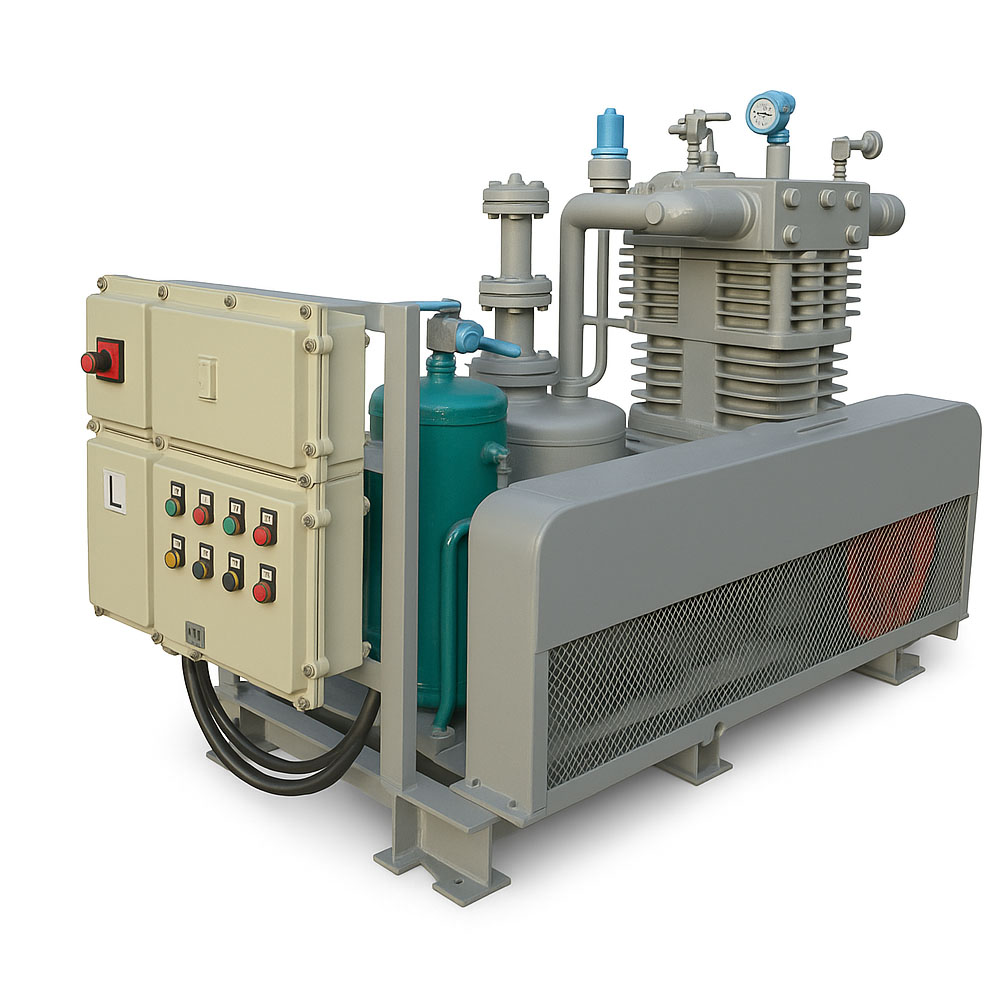

- Custom Engineering:Available in horizontal or vertical arrangements, with options for air-cooled or water-cooled systems, depending on installation environment and process requirements.

- Superior Sealing Technology:Advanced sealing systems minimize gas leakage, reduce emissions, and extend service intervals—ideal for CO₂ and other volatile gases.

- High Reliability:Designed with robust frames and low-speed crankshafts to reduce wear and extend service life even under continuous operation.

- Flexible Control Systems:Supports modern automation with PLC/HMI interfaces, real-time temperature and pressure monitoring, and compatibility with variable frequency drives (VFDs).

Advantages of the CO Reciprocating Compressor

- High Efficiency:Optimized piston and cylinder design reduces energy loss and improves isothermal efficiency.

- Low Maintenance Costs:Easy-to-replace valve assemblies, wear parts, and modular construction reduce downtime and service effort.

- Versatile Gas Handling:Capable of compressing inert, flammable, corrosive, or reactive gases with proper material selection.

- Emission Compliance:Meets strict environmental regulations by integrating oil-free designs or minimal leakage sealing packages.

- Compact Skid-Mount Option:Available as skid-mounted units for simplified installation and on-site commissioning.

Application Scenarios

- CO₂ gas compression for sequestration, beverage carbonation, or dry ice production

- Natural gas pipeline booster or CNG station compressor

- Hydrogen fuel compression and storage systems

- Ammonia and urea production plants

- Industrial air separation and synthetic gas processing

Why Choose Our CO Reciprocating Compressor?

Whether you’re operating a gas recovery system, a chemical production plant, or a hydrogen refueling station, the C0 reciprocating compressor provides the efficiency, flexibility, and safety you need. Engineered for long-term operation in challenging environments, this compressor offers excellent performance, minimal emissions, and tailored configurations to fit your process perfectly.