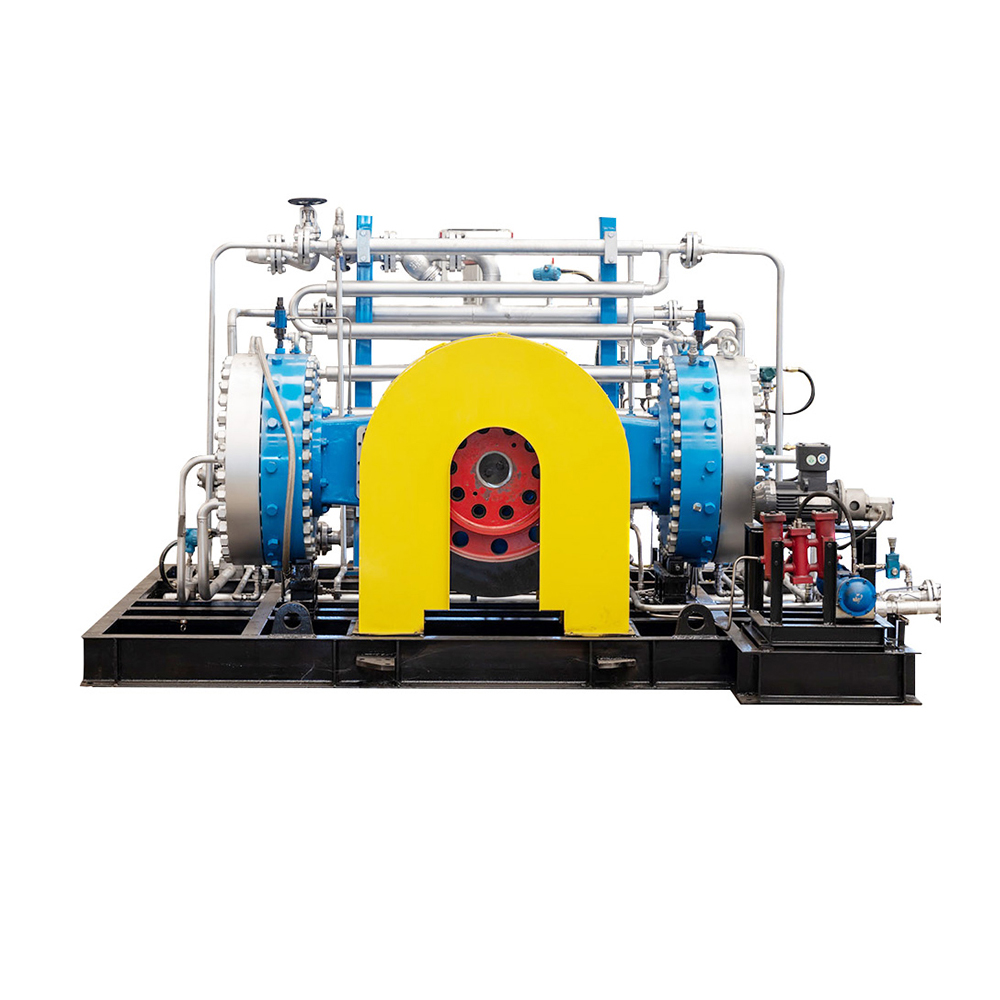

Ar Reciprocating Compressor

Home > Products > Diaphragm Compressor >

Ar Reciprocating Compressor

- Power Range: 5–200 kW (7–270 HP)

- Inlet Pressure: Normal pressure (approx. 0 bar)

- Discharge Pressure: 1–30 bar(Customizable higher)

- Discharge Flow: 1–2000 Nm³/h

- Speed: 750–1500 rpm(Depends on the drive mode)

- Lubrication: Splash or Pressure

- Cooling: Air or Water Cooling

- Cylinder Material: Cast Iron or Alloy

Get Free Quote

AR Reciprocating Compressor, also known as piston compressor or plunger compressor, is a widely used positive displacement machine. It is commonly applied in power ranges up to 30 HP (22 kW), with discharge pressures ranging from 80 to 250 PSIG (approx. 5.5–17 bar). The crankshaft drives the piston in a reciprocating motion, compressing gas through volume reduction of the cylinder.

This compressor features a compact structure, high reliability, and low installation cost, making it ideal for various industrial and commercial applications.

Operating Principle & Types

It operates based on the positive displacement principle, where a piston reciprocates inside the cylinder to draw in, compress, and discharge gas.

By Function Type:

- Single-acting:Compression occurs on one side of the piston. Simple and easy to maintain.

- Double-acting:Both sides of the piston compress gas. Higher efficiency, suitable for heavy-duty use.

- Diaphragm type:Uses a flexible diaphragm instead of piston; ideal for handling special gases.

By Compression Stages:

- Single-stage:Typically used for pressures up to 125 PSI (8.6 bar).

- Multi-stage:Designed to incrementally compress gas to higher pressures up to several hundred or thousand PSI.

Product Features

- Compact Design:Modular structure for flexible installation.

- Wide Pressure Range:Supports 1–30 bar (higher on request), suitable for various sectors.

- Flexible Lubrication:Choose between splash or pressure lubrication depending on the application.

- Efficient Cooling:Air-cooled or water-cooled systems ensure thermal stability.

- High Reliability:Ideal for frequent start-stop and heavy-duty operation.

- Multiple Drive Options:Available with electric, diesel, or gas engine drives.

Advantages

- Durable and Reliable:Low maintenance, continuous stable performance

- Energy Efficient:High partial load efficiency, low idle consumption

- Start-Up Friendly:Unloaded start feature extends motor life

- Optimized Cooling:Finned cylinder design improves thermal control

- Flexible Options:Supports add-ons like receiver tanks, aftercoolers, auto drains, and PLC control

Applications

- Heavy-Duty and Intermittent Operations:Auto repair shops, construction sites, amusement parks

- Small to Mid-Sized Industries:Food & beverage, woodworking, petrochemicals, gas transmission