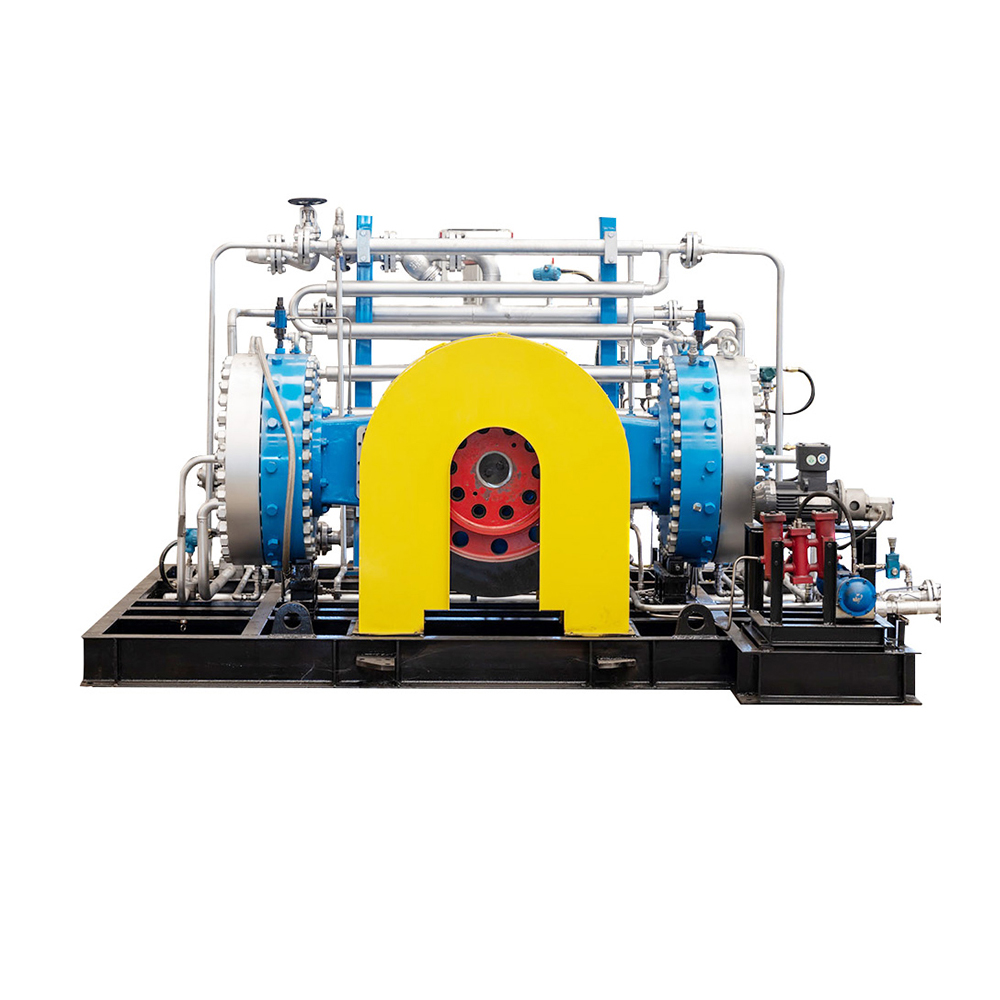

H2S diaphragm compressor

H2S diaphragm compressor

- Compressor structure: GL type Diaphragm Compressor

- Piston stroke: 110mm-180mm Volume

- Flow: 3NM3/hour~1000NM3/hour (customized)

- Voltage: 380V/50Hz (customized) Maximum outlet pressure:100MPa (customized)

- Motor power: 11KW~90KW (customized)

- Noise: <80dB

- Crankshaft speed: 350~420 rpm/min

- Certificate: ISO9001, CE certificate, etc.

- Advantages: High-efficiency exhaust pressure, zero pollution to the compressed gas, excellent sealing performance, and corrosion-resistant materials available as options.

Product Description:

A diaphragm compressor designed specifically for handling hydrogen sulfide (H₂S) gas is a high-performance, positive displacement compressor known for its ability to compress hazardous, reactive gases with absolute purity and without leakage or contamination. Unlike traditional piston compressors, this type of compressor uses a flexible diaphragm, actuated hydraulically, to completely isolate the compressed gas from the crankcase and piston, ensuring safe and reliable operation.

Key Features:

-

Hermetic Sealing: The metal or elastomer diaphragm forms a full, leak-proof barrier, preventing any contact between the compressed H₂S gas and the hydraulic fluid or lubricants. This is crucial for maintaining purity.

-

Zero Contamination: Ensures that the compressed H₂S gas remains entirely oil-free, with no risk of contamination from lubricants, wear particles, or other impurities. This is vital for maintaining the integrity of sensitive gas applications.

-

Leak Prevention: Designed to prevent fugitive emissions, making it the ideal solution for safely handling toxic, flammable, or environmentally hazardous gases like H₂S, which require airtight containment.

-

High Pressure Capability: Built to achieve high discharge pressures, typically up to 3000 bar (43,500 psi) and beyond, especially in multi-stage configurations, ensuring efficient compression even at extreme pressures.

-

Versatile Gas Handling: Perfect for compressing a wide range of gases, particularly those that are corrosive, reactive, or hazardous, such as hydrogen sulfide, where other compressors might introduce contamination or fail due to the aggressive nature of the gas.

-

Moderate Flow Rates: Typically designed for low to medium flow rates, making it ideal for applications requiring precise control of H₂S gas, as opposed to large reciprocating or centrifugal compressors.

| Model | Cooling water consumption (t/h) | Displacement (Nm³/h) | Intake pressure (MPa) | Exhaust pressure (MPa) | Dimensions L×W×H(mm) | Weight (t) | Motor Power (kW) | |

| 1 | GL-10/160 | 1 | 10 | 16 | 2200×1200×1300 | 1.6 | 7.5 | |

| 2 | GL-25/15 | 1 | 25 | 1.5 | 2200×1200×1300 | 1.6 | 7.5 | |

| 3 | GL-20/12-160 | 1 | 20 | 1.2 | 16 | 2200×1200×1300 | 1.6 | 7.5 |

| 4 | GL-70/5-35 | 1.5 | 70 | 0.5 | 3.5 | 2000×1000×1200 | 1.6 | 15 |

| 5 | GL-20/10-150 | 1.5 | 20 | 1.0 | 15 | 2200×1200×1300 | 1.6 | 15 |

| 6 | GL-25/5-150 | 1.5 | 25 | 0.5 | 15 | 2200×1200×1300 | 1.6 | 15 |

| 7 | GL-45/5-150 | 2 | 45 | 0.5 | 15 | 2600×1300×1300 | 1.9 | 18.5 |

| 8 | GL-30/10-150 | 1.5 | 30 | 1.0 | 15 | 2300×1300×1300 | 1.7 | 11 |

| 9 | GL-30/5-160 | 2 | 30 | 0.5 | 16 | 2800×1300×1200 | 2.0 | 18.5 |

| 10 | GL-80/0.05-4 | 4.5 | 80 | 0.005 | 0.4 | 3500×1600×2100 | 4.5 | 37 |

| 11 | GL-110/5-25 | 1.4 | 110 | 0.5 | 2.5 | 2800×1800×2000 | 3.6 | 22 |

| 12 | GL-150/0.3-5 | 1.1 | 150 | 0.03 | 0.5 | 3230×1770×2200 | 4.2 | 18.5 |

| 13 | GL-110/10-200 | 2.1 | 110 | 1 | 20 | 2900×2000×1700 | 4 | 30 |

| 14 | GL-170/2.5-18 | 1.6 | 170 | 0.25 | 1.8 | 2900×2000×1700 | 4 | 22 |

| 15 | GL-400/20-50 | 2.2 | 400 | 2.0 | 5.0 | 4000×2500×2200 | 4.5 | 30 |

| 16 | GL-40/100 | 3.0 | 40 | 0.0 | 10 | 3700×1750×2000 | 3.8 | 30 |

| 17 | GL-900/300-500 | 3.0 | 900 | 30 | 50 | 3500×2350×2300 | 3.5 | 55 |

| 18 | GL-100/3-200 | 3.5 | 100 | 0.3 | 20 | 3700×1750×2150 | 5.2 | 55 |

| 19 | GL-48/140 | 3.0 | 48 | 0.0 | 14 | 3800×1750×2100 | 5.7 | 37 |

| 20 | GL-200/6-60 | 3.0 | 200 | 0.6 | 6.0 | 3800×1750×2100 | 5.0 | 45 |

| 21 | GL-140/6-200 | 5.0 | 140 | 0.6 | 20.0 | 3500×1380×2350 | 4.5 | 55 |

| 22 | GL-900/10-15 | 2.5 | 900 | 1.0 | 1.5 | 3670×2100×2300 | 6.5 | 37 |

| 23 | GL-770/6-20 | 4.5 | 770 | 0.6 | 2.0 | 4200×2100×2400 | 7.6 | 55 |

| 24 | GL-90/4-220 | 6.0 | 90 | 0.4 | 22.0 | 3500×2100×2400 | 7.0 | 45 |

| 25 | GL-1900/21-30 | 3.8 | 1800 | 2.1 | 3.0 | 3700×2000×2400 | 7.0 | 55 |

| 26 | GL-300/20-200 | 4.2 | 300 | 2.0 | 20.0 | 3670×2100×2300 | 6.5 | 45 |

| 27 | GL-200/15-200 | 4.0 | 200 | 1.5 | 20.0 | 3500×2100×2300 | 6.0 | 45 |

| 28 | GL-330/8-30 | 5.0 | 330 | 0.8 | 3.0 | 3570×1600×2200 | 4.0 | 45 |

| 29 | GL-150/6-200 | 5.0 | 150 | 0.6 | 20.0 | 3500×1600×2100 | 3.8 | 55 |

| 30 | GL-300/6-25 | 4.5 | 300 | 0.6 | 2.5 | 3450×1600×2100 | 4.0 | 45 |